MOLDS PRODUCTION

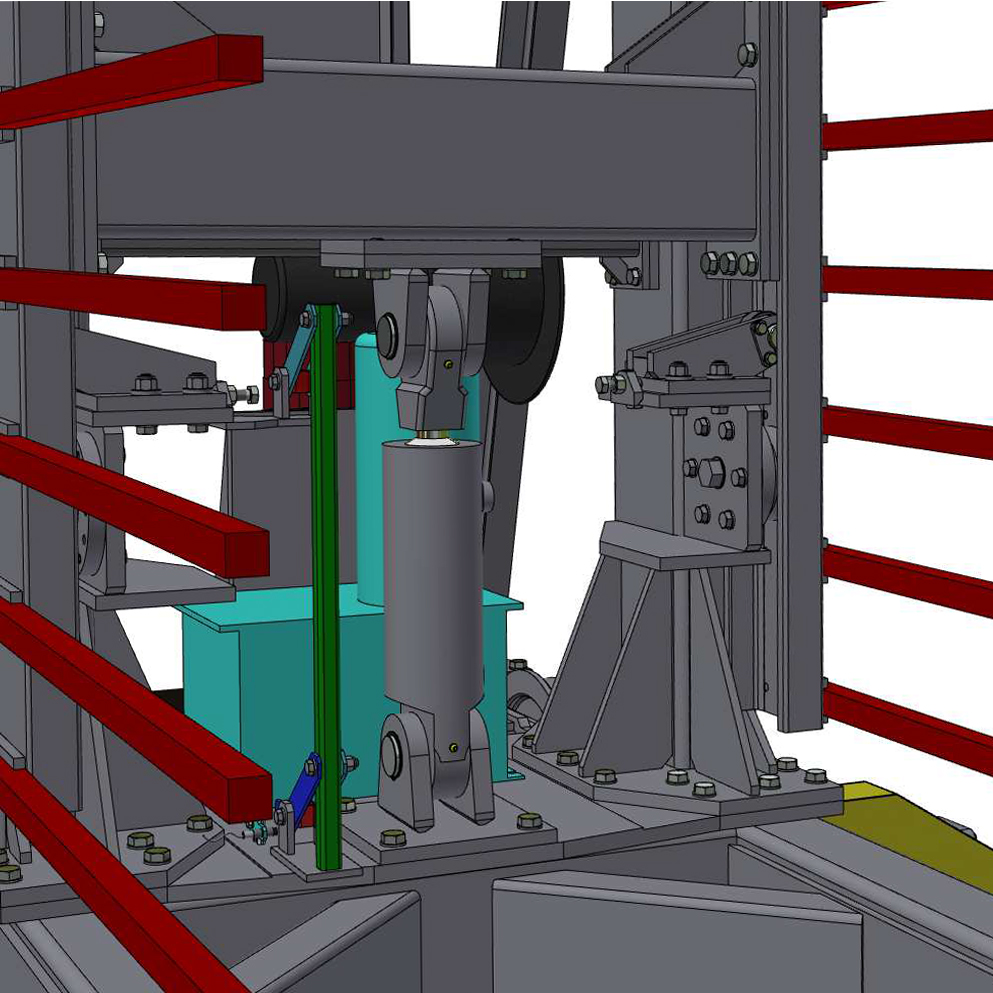

The molds are manufactured according to the company’s own standards, which are more restrictive than the general European standards. The entire mold production process and services related to their servicing are supervised by a qualified team of constructors and technologists, which allows for continuous improvement of technological processes.

Co-operation with producers of concrete products allows us to test new solutions directly during normal production conditions on our customers’ machines.

The materials needed for the production of molds are purchased from a world-renowned steel producer. Each batch of material is delivered with the required certificates, which allows us to ensure the highest quality of the finished product.

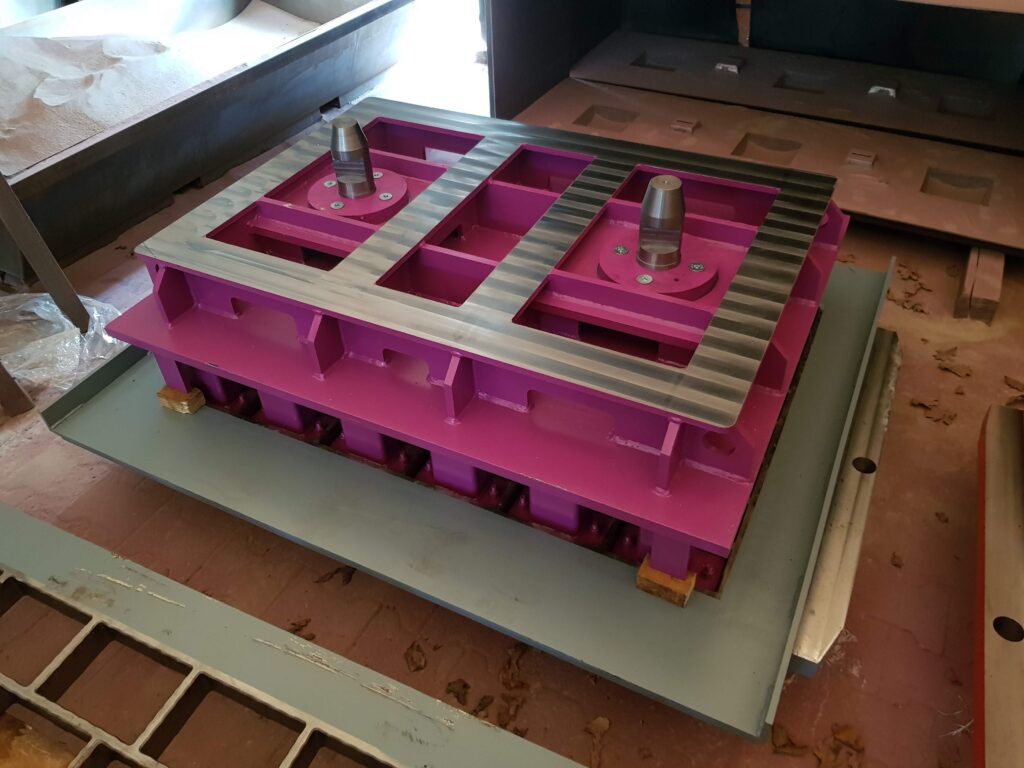

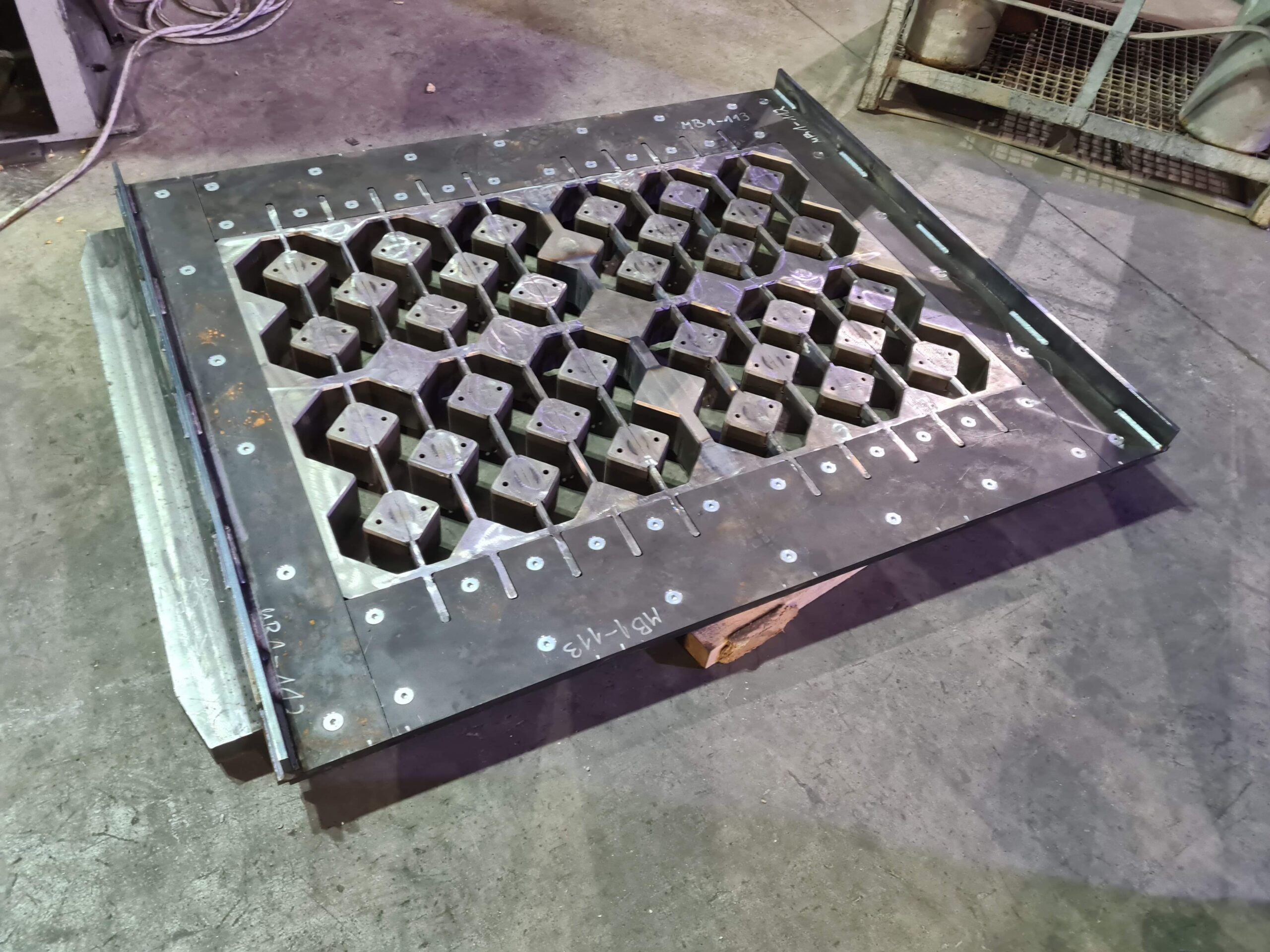

The molds are machined on a CNC machines, thanks to this we achieve precise cavities’ dimensions. The mold inserts are subject to a thermo-chemical treatment process, which ensures obtaining the appropriate depth of hardening and hardness of the working surface. Thanks to thermo-chemical treatment, we obtain products that match the quality of products of internationally recognized foreign mold manufacturers.

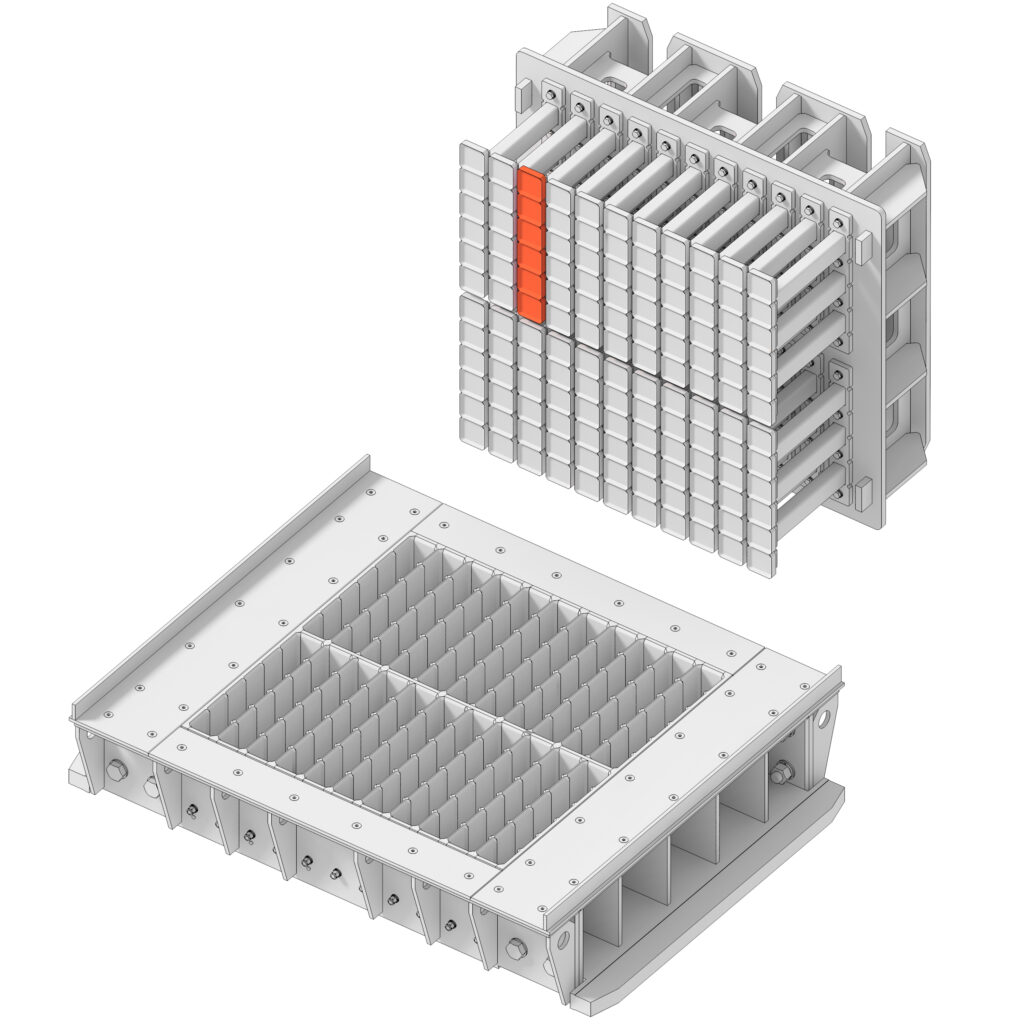

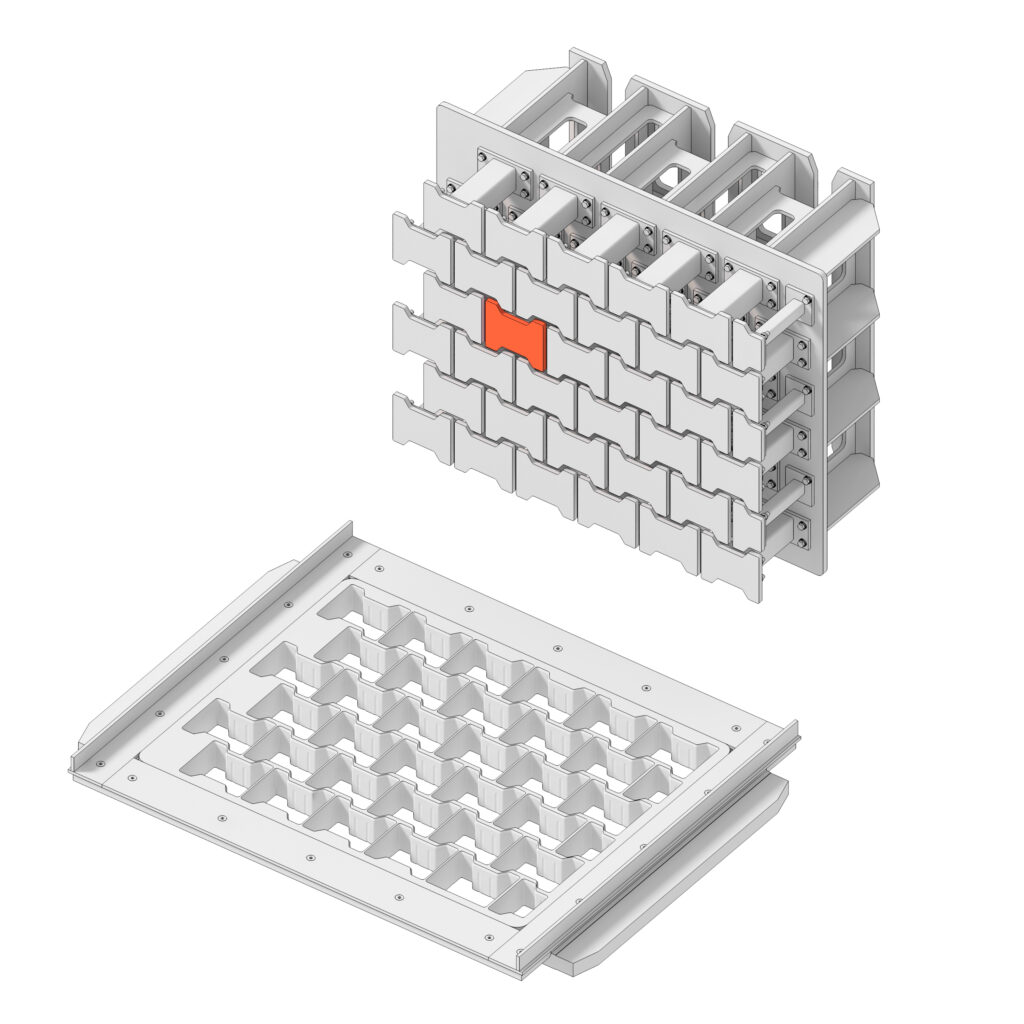

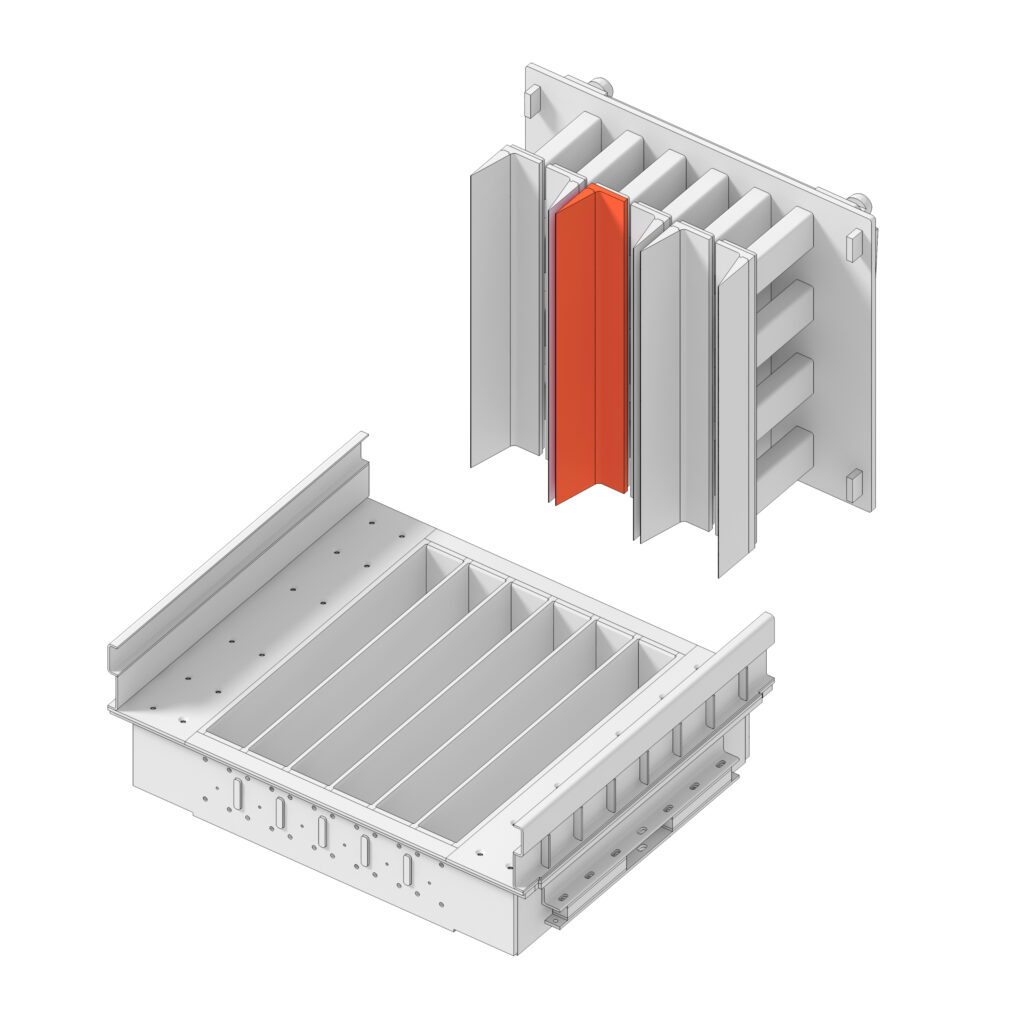

We offer steel molds for the production of paving stones and concrete decorative elements, tailored to the individual needs of our customers and meeting the highest quality standards. Machining of mold cavities and tamper head shoes is performed on CNC machining centers, which guarantee the accuracy of machining of molds, accuracy of dimensions and repeatability of mold production. After CNC and thermo-chemical treatment, all mold cavities are measured with a FARO measuring device. Tamper head shoes are produced on a base of obtained measurements results and fit into a given mold cavity. Tamper head shoes are made with an allowance of 0,3 ÷ 0,4 mm for paver molds and with allowance of 0,4 ÷ 0,6 mm for molds for the production of high elements. Application of the above-mentioned allowances results in a longer lifetime of the molds and allows to achieve the highest quality concrete products.

FARO measuring device is equipped with a scanning head, which allows us to scan the surface of the stones. On a base of scans, we are able to produce molds for a production of concrete products with “a natural stone surface” effect.

Mold refurbishment and repair

We offer a service of mold refurbishment and repair for our customers. The reuse of some mold components (such as: tamper head, mold frame) allows our customer to lower the costs of mould exploitation in compare to the production of a completely new mold.

We offer two types of moulds’ refurbishment and repair.

-

- Small repair covers the repair of a mold that has worked a certain number of cycles and there are first signs of wear.

The exemplary scope of work includes:

– mold cleaning and visual inspection, determination of the scope of works and pricing of a mould repair

– preparation of technical and technological documentation

– surfacing / welding of wear, cracks and cavities of the mould bottom (traces of feeding drawer operation, “elephant feet”)

– repair of the tamper head (welding of cracks, milling tamper head’s surface, replacing of damaged plungers – if necessary)

– production of a new tamper head shoes

– production of a new core-bars and new cores (for Meba molds, hollow block moulds)

– assembling and painting of the mold

– packaging and shipping to the customer

-

- “Big” refurbishment and repair includes production and assembling of a new bottom mould and set of tamper head shoes with tamper head delivered by the customer.

The exemplary scope of work includes:

– cleaning and visual inspection of a tamper head, determination of the scope of works and pricing of tamper head repair

– pricing of a production of a new bottom mold and set of tamper head shoes

– preparation of technical and technological documentation for production of a new bottom mold with set of tamper head shoes

– tamper head repair (e.g. welding of cracks, milling tamper head’s surface, replacing of damaged plungers – if necessary)

– production of a new bottom mold and set of tamper head shoes

– assembly of the bottom mold and set of tamper head shoes with a tamper head

– painting the mold

– packaging and shipping to the customer

At the customer’s request, we will organize the transport of molds to our plant, as well as back to the customer’s plant.

OTHER PRODUCTS

Our range of products also includes:

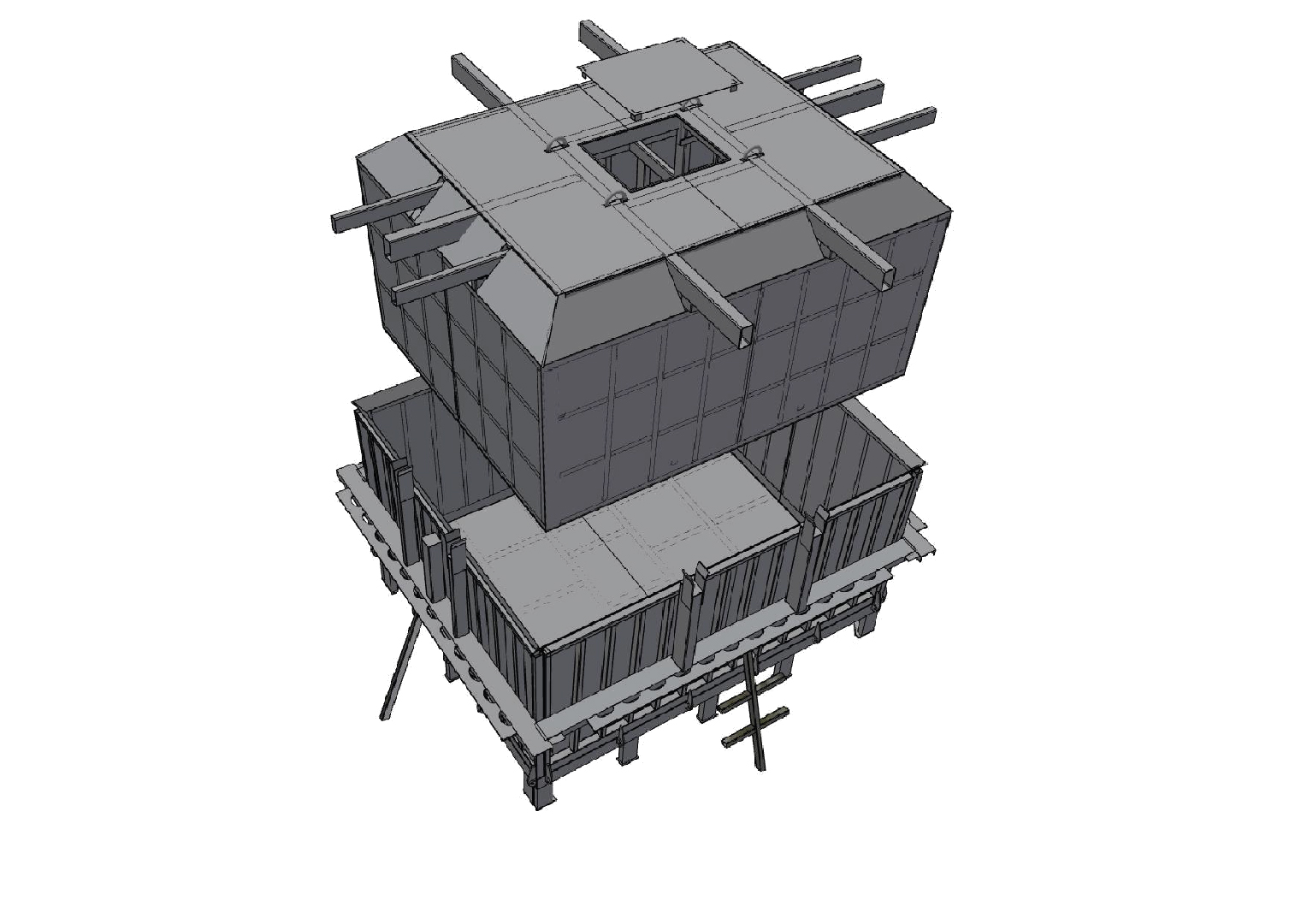

– Molds for cesspools

– Molds for garden cellars

– Molds for big blocks “Lego”

– Cement silos

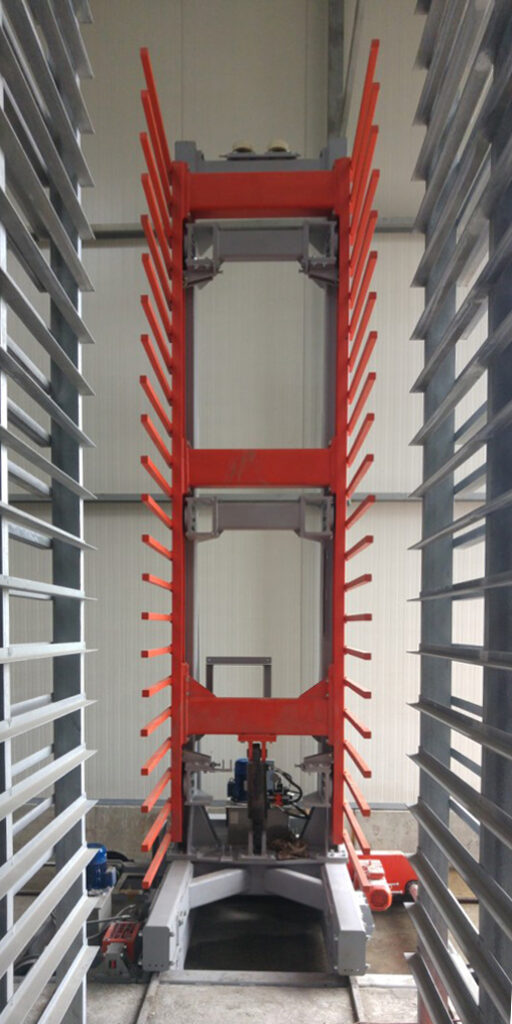

– Equipment and complete technological lines for the production of paving stones and concrete decorative elements

– Concrete batching & mixing plants

The Company was founded in Radom in 2013. The Company designs and produces machines and devices included in the technological line for the production of vibro-pressed concrete products, batching and mixing plants, as well as other machines and devices required in this type of production.

The Company moved its production plant to a newly built production hall located in Wolanów near Radom in 2018. Since then, products range has been extended with high-quality steel molds for production of paving stones and concrete decorative elements.

The Company’s team consists of people with many years of experience in this industry, starting from the owner himself, who has over 17 years of experience in the practical design, improvement and production of machines, through a team of constructors, CNC machines operators, gas and laser cutters operators, to welders and assemblers of finished products.

Each device or mold is manufactured in accordance with customer’s requirements, while meeting the requirements of its own factory standards, which are much more restrictive than Polish and European standards.

The Company constantly extends its portfolio of machines and devices to meet customers’ expectations.

We invite you for co-operation.

CONTACT US

PHONE:

+48 577 907 929

+48 511 500 412

COMMERCIAL DIRECTOR:

M.PAWLAK@STAMPFOR.PL

OFFICE:

BIURO@STAMPFOR.PL

SERVICE DEPARTMENT:

SERWIS@STAMPFOR.PL

ADDRESS:

ul. RADOMSKA 32

26-625 WOLANÓW

POLAND